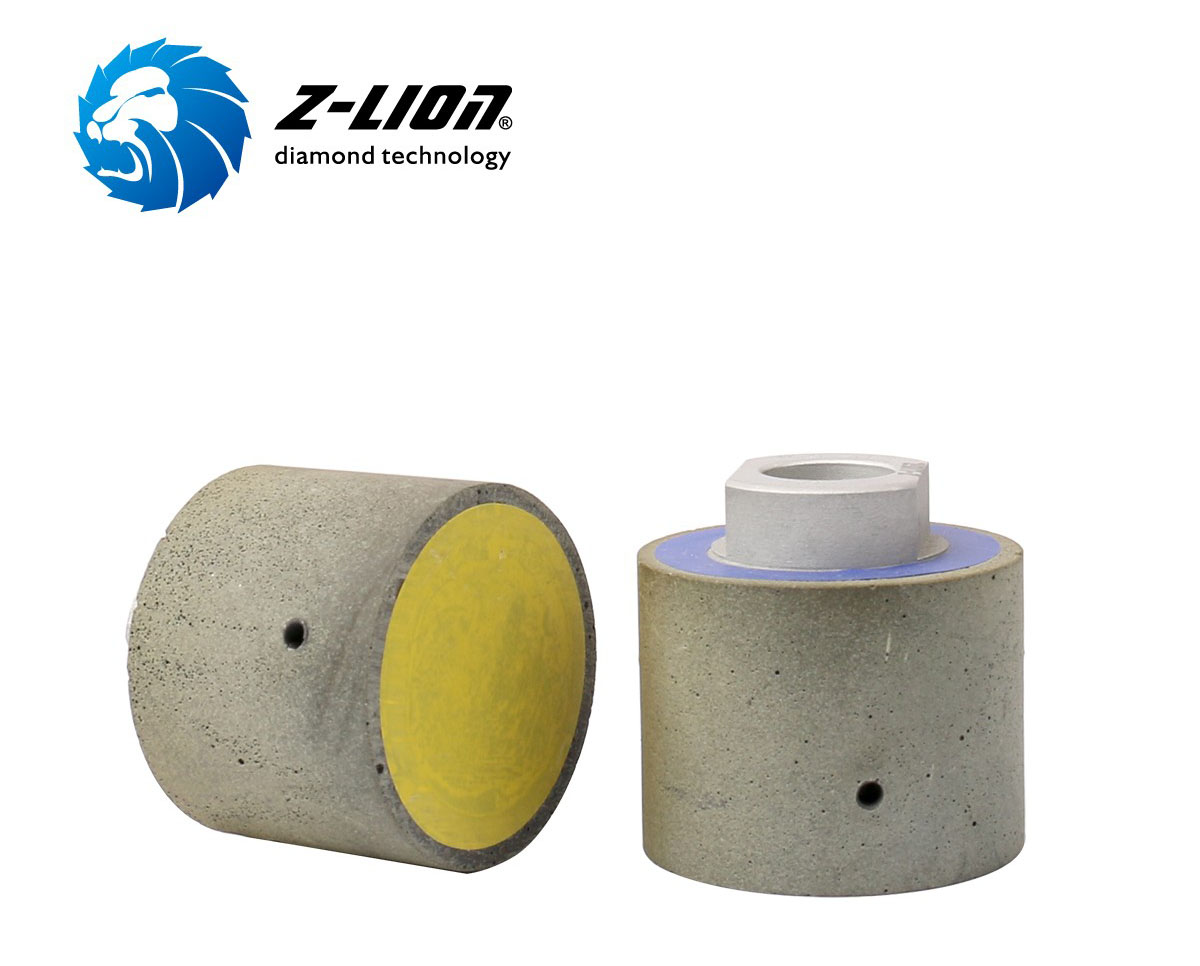

Resin diamond grinding wheel and electroplated diamond grinding wheel

When it comes to industrial applications, having the right tools is essential. The two most common types of grinding wheels are resin diamond grinding wheels and electroplated diamond grinding wheels. While they look similar on the surface, there are some notable differences between the two.

One of the main differences between these two types of grinding wheels is the adhesive used. Resin diamond grinding wheels use phenolic resin and a small amount of metal powder to bond diamond abrasive grains together. The result is a flexible and versatile tool that can be used for grinding a wide variety of materials, including hard metals, glass, ceramics, and stone. Resin diamond wheels also generate less heat, resulting in higher-quality grinding results. In contrast, electroplated diamond wheels use a deposition process to bond diamond grit to a metal substrate. The process involves depositing a nickel-cobalt alloy onto the surface of a metal substrate using electrodeposition. After the metal coating is complete, a nickel or chromium coating is used to bond the diamond grit to the surface. The result is a durable and strong grinding wheel ideal for grinding materials such as synthetics, plastics, and non-metals.

The main difference in their performance is that:

First, resin diamond wheels use a bond made of phenolic resin and metal powder to hold the diamond grains together. This creates a versatile wheel that can efficiently grind hard metals, ceramics, glass, stone, and other materials. This type of grinding wheel generates less heat, so higher-quality grinding results can be achieved with minimal surface damage. Electroplated diamond grinding wheels, on the other hand, use an electrodeposition process to bond diamond abrasive grains to a metal substrate. This type of grinding wheel has only one layer of abrasive. Due to the use of high-grade abrasives, the heat dissipation performance is excellent, and the processing efficiency of the electroplated diamond grinding wheel is higher.

Another factor to consider is their machining accuracy. Electroplated diamond wheels produce higher surface roughness when using the same grit size. This means that the impact on the workpiece is more pronounced than with resin diamond wheels. In contrast, resin diamond wheels produce smoother surfaces and better precision during the grinding process. Therefore, selecting the right type of grinding wheel for a specific industrial application is critical. If precision and smooth surfaces are critical, resin diamond grinding wheels are the first choice. But if speed and efficiency are required, then electroplated diamond grinding wheels are a more suitable choice. To sum up, the difference between a resin diamond grinding wheel and an electroplated diamond grinding wheel lies in its abrasive grain retention mechanism, service life, efficiency, and machining accuracy.

In conclusion, while there are similarities between resin diamond grinding wheels and electroplated diamond grinding wheels, differences in their bonds and efficiencies can greatly affect their performance and effectiveness. As with any tool, understanding the unique properties of each grinding wheel is critical to making the right selection for your specific industrial application.

English

English  Português

Português  русский

русский  Chinese

Chinese  French

French  Japanese

Japanese  Spanish

Spanish  Italian

Italian