Stone Polishing: Sandpaper Selection

To obtain a perfectly polished stone, the choice of sandpaper and the characteristics of the stone itself play a vital role in determining the outcome of the polishing process. Understanding the interaction between these elements is crucial to achieving a flawless, lustrous finish that highlights the stone's inherent beauty.

The first step in your stone polishing journey revolves around the careful selection of the stone itself. While any gemstone can undergo the polishing process, it has been proven that gemstones with certain properties are better suited to polishing, resulting in a smoother, more refined surface. Choosing a softer gemstone, such as agate, limestone, or calcite, can simplify the polishing process and reduce the time and effort required to achieve the desired shine. Conversely, a stone with a harder composition may take longer to polish, but the final product will be more radiant and lustrous. Determining the softness of the stone is a key factor in the stone selection process. A simple and effective way to tell the softness of a stone is to scratch it with another stone. If the scratches on the stone appear white, it indicates that it is softer, making it more suitable for a simplified polishing process. Additionally, choosing a nearly round stone with minimal protrusions or depressions can make the polishing process more efficient, ensuring a more even and consistent finish.

Clean the stone by washing it thoroughly with soap and water and then using a brush to remove any stubborn stains or residue. After cleaning, pat the stone dry to complete the process.

Shape the stone. If you want the stone to be rounder, use a small hammer or chisel to chip away at the excess stone bit by bit. Wear safety goggles to protect your eyes from stone debris. If you wish, you can also wear safety gloves. Chisel away the protruding parts of the stone. If you like the original shape of the stone, there is no need to change it. You can also grind the stone over the concrete slab to remove any protrusions.

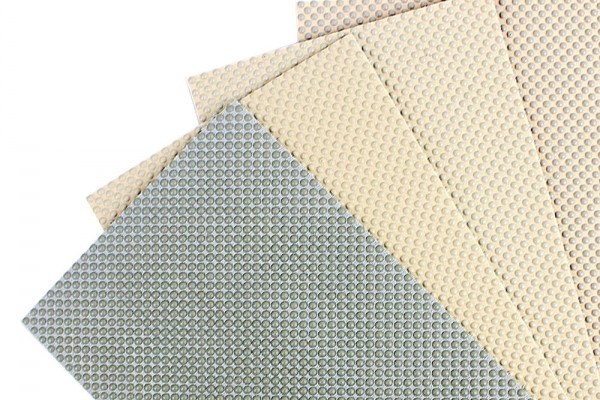

Start by using 30-grit sandpaper to smooth the stone and remove any bumps or bumps. This coarsest sandpaper will effectively shape the stone to your desired specifications. Use sandpaper to gradually refine the outline and overall shape of the stone. Once you're happy with the initial shape, sand the entire surface evenly with 30-grit sandpaper to make it smooth.

After you complete the initial molding, you may notice scratches from the 30-grit sandpaper. To fix this, use 120-grit sandpaper to further smooth the stone and remove any visible scratches. This finer grade of sandpaper helps refine the stone surface and prepare it for the final polishing stage.

In the final stage, use 200 to 600-grit sandpaper for a high-quality finish. Start with 200-grit sandpaper and gradually increase to 600-grit sandpaper. Focus on polishing the entire surface of the stone while paying special attention to any remaining scratches. Fine-grit sandpaper effectively removes any imperfections and ensures a smooth surface.

Once the grinding process is complete, the stone is ready for its final polish. Use a polishing cloth and apply a small amount of polish or diamond paste to the stone. Rub the compound into the surface of the stone in a circular motion, applying gentle pressure. This step further enhances the stone's luster and shine for a professional-grade finish.

Other notes: Keep the stone and sandpaper moist during polishing to prevent heat build-up and help remove abrasive particles. When using sandpaper, be methodical and make sure to evenly cover the entire surface of the stone for a consistent result. Particularly hard stones, such as granite or quartz, may require specialized diamond polishing disc to polish effectively.

All in all, learning how to polish stone requires patience, attention to detail, and the right tools. By following these step-by-step guides and completing each stage carefully, you can transform a rough stone into a beautifully polished masterpiece. Whether you pursue gemstone working as a hobb

English

English  Português

Português  русский

русский  Chinese

Chinese  French

French  Japanese

Japanese  Spanish

Spanish  Italian

Italian