Use the right blade for perfect tiles

1. What blade to use for cutting tiles?

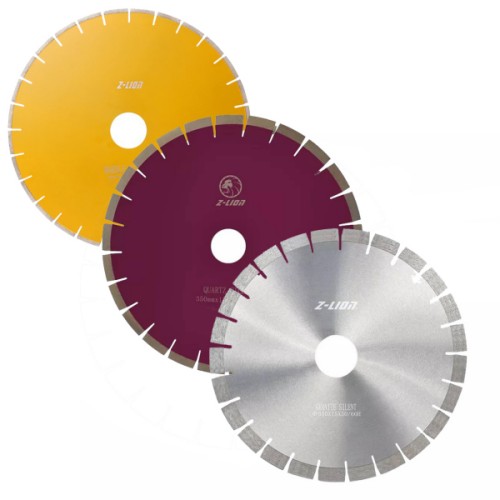

When it comes to cutting ceramic tiles with precision and ease, diamond cutting blades are the top choice among professionals and DIY enthusiasts alike. Made using a powder metallurgy process, these blades offer excellent wear resistance and toughness, making them a popular choice for cutting tiles and various metals. Let’s dive into the specifics of these cutting blades to ensure you get the results you need.

The manufacturing process of diamond cutting blades is to embed diamond particles into metal powder and then sinter them. This process fuses diamond particles and metal together to create a powerful combination that can withstand the rigors of tile cutting. The blade is then shaped using a grinding wheel, removing the surrounding metal and exposing the diamond particles. These exposed diamond particles act as cutting edges, forming what is called a cutting blade.

When it comes to tile cutting, there are several advantages to using a diamond cutting blade. First, their wear resistance ensures durability, allowing the blades to withstand the demands of continuous cutting without losing their effectiveness. Secondly, the toughness of these blades allows them to withstand the pressure exerted during tile cutting, preventing breakage and ensuring longevity. Their ability to cut both tile and metal adds to their versatility, making them a reliable choice for a variety of cutting needs.

When choosing a diamond cutting blade, you must consider the specific requirements of your project. Different blades have different specifications, including size, thickness, and the type of material they are designed to cut. Additionally, the quality and grade of diamond used in the blade will determine its performance and durability. Therefore, it is crucial to choose a high-quality diamond-cutting blade that is suitable for your specific tile-cutting needs.

In order to achieve precise tile cuts, it is important to ensure that the blade is installed correctly and clamped securely. This will ensure stability and minimize the risk of chipping or improper cutting. Additionally, using water as a coolant during the tile-cutting process improves the performance of the blade and extends its service life.

It's worth noting that while diamond-cutting discs work great at cutting ceramic tile, they may not be ideal for cutting other materials like glass or porcelain. These materials require specialized blades designed specifically for their unique properties.

All in all, diamond cutting blades are widely regarded as the most efficient and reliable option for cutting ceramic tiles. Their wear resistance, toughness, and versatility make them a popular choice among the construction and DIY communities. By choosing the right type and quality of the diamond cutting blade and following the correct installation techniques, you can achieve the perfect tile cut for your next project.

2. Proper maintenance tips for optimizing your cutting machine.

Cutting machines are essential tools in every industry, enabling precision cuts and increased productivity. To ensure its seamless operation and longevity, regular maintenance is essential. Here are some great tips to help you maintain your cutting machine effectively.

Safety first: Disconnect power

Before starting any repair or maintenance work on the cutting machine, it is important to disconnect the power source. This precaution ensures operator safety and prevents accidental injury.

Diamond Saw Blades: Understanding their limitations. For ceramic cutters, the tool of choice is usually a diamond saw blade. It is important to note that diamond saw blades are not designed for cutting metal materials or curves. Attempting to use a diamond saw blade to cut metal or make curved cuts may cause damage to the blade and may impair its functionality.

Replace blade: Check for damage. When replacing the blade with a new one, carefully inspect it for any cracks, chips, or bends. A damaged blade can result in poor cut quality and pose a safety risk. If you notice any signs of damage or wear, it is recommended to replace the blade with a new one immediately.

Blade sharpness: Maintain optimal cutting performance. Using a dull saw blade can cause motor failure, resulting in inefficient operation. To overcome this problem, replace dull blades regularly or consider using the refractory brick cutting and sharpening method to restore their sharpness.

Motor activation: Automatic protection mode. If your cutting machine stops during use, it may indicate that the motor has entered automatic protection mode. In this case, you need to remove the protection and let the motor rest for a period of time. After that, you can turn the machine on again to make sure the motor is running smoothly.

Grounded power supply: Ensuring electrical safety. To prevent electrical accidents, make sure the power supply of the cutting machine is properly grounded. This helps minimize the risk of electric shock and protects the machine from potential power surges.

Child Safety: Keep the machine out of reach. Never open or operate the cutter in the presence of children. These machines have sharp parts that can cause serious hazards if not handled properly. Make sure to place the cutter in a safe area out of the reach of children to prevent accidents.

By following these maintenance guidelines, you can optimize your cutting machine's performance, extend its service life, and ensure a safe work environment. Remember to prioritize safety measures and address any issues promptly to avoid complications during the procedure.

English

English  Português

Português  русский

русский  Chinese

Chinese  French

French  Japanese

Japanese  Spanish

Spanish  Italian

Italian