Analysis of the use method and application of diamond wet grinding disc

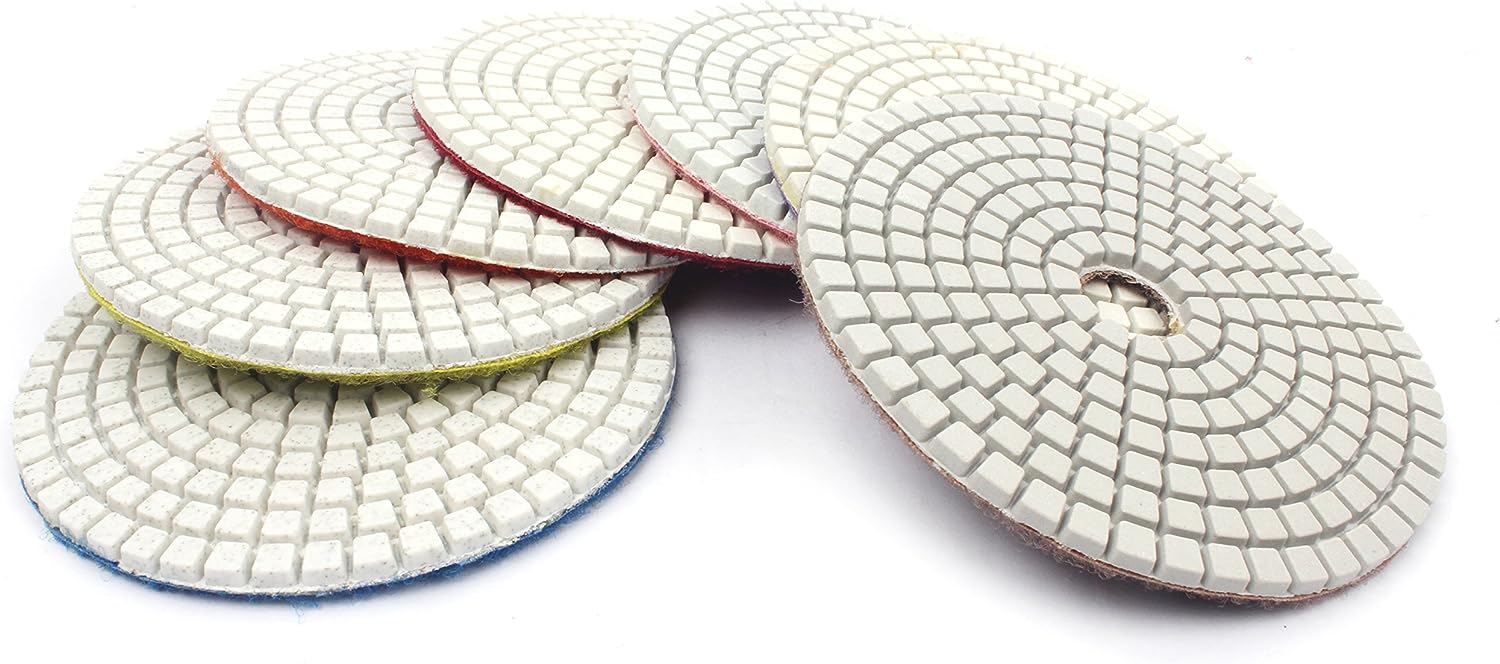

Diamond wet grinding disc is a relatively common abrasive tool for grinding stone. This kind of abrasive tool uses diamond as the main raw material and combines it with composite materials to make abrasive tools. It is mainly used for stone, ceramics, glass, floor tiles and other materials. Special-shaped processing and other purposes. Most people don't know much about the use of diamond wet grinding discs. Let's learn about it with Z-LION today.

How to use diamond wet grinding discs?

Preparation: Before starting the sanding process, it is crucial to properly prepare the floor. Start by using a knife to remove any concrete grout or debris in the gaps between the stones. Next, use a brush, vacuum, or other cleaning tool to remove dust and grime. Finally, use a dry and clean mop to make sure the ground is free of sand and debris.

Grinding Technology: To start grinding, you need to attach a diamond wet grinding disc to a portable electric or air grinder. When using a grinding disc, it is important to apply some pressure on the machine while running water over the surface of the stone being ground. This ensures proper lubrication and prevents overheating of the discs and damage to the stones. Start the grinding process by going back and forth on the surface of the stone 4-5 times. After this step, change to a finer disc and repeat the grinding process a total of seven times. After the grinding process is complete, the floor should appear flat and smooth overall. To achieve the desired brilliance, finish the process by buffing the surface with steel wool.

Treat polished floors: After polishing, it is very important to remove any residual moisture on the floor. Use a suction machine to absorb excess water from the surface. At the same time, use a hair dryer to ensure that the entire stone floor is thoroughly dry. Alternatively, if time permits, you can allow the stone surface to air dry.

The use of diamond water grinding disc

1. Stone Processing

Diamond wet grinding discs have a complete and standardized particle size and color system. This ensures consistency and accuracy in the grinding process. The standardized system can easily identify the properties of discs, making it convenient for users to choose the right disc according to their specific needs. In addition, diamond wet grinding discs have excellent flexibility and are ideal for machining chamfers, lines, curved slabs, and shaped stones. This flexibility enables precise and complex milling, allowing artisans to obtain the desired shape and finish. Whether shaping edges or creating intricate designs, these discs provide the control and precision necessary. In addition, diamond wet grinding discs are available in various shapes and specifications, providing users with options to meet their requirements. The availability of different shapes and sizes ensures versatility for stone processing tasks. Users can easily adapt these discs to a variety of manual grinders for seamless integration with their preferred tools and work habits.

2.Ground Treatment and Refurbishment

Diamond wet grinding discs are a versatile and effective tool when it comes to floor preparation and refurbishment. These discs are specially designed to handle floors and steps made of granite, marble, and engineered stone slabs. One of the main advantages of diamond wet grinding discs is their flexibility. They can be easily paired with a variety of hand grinders or reconditioning machines. This means that no matter your specific needs and preferences, there is a compatible tool to make the job easier. Whether you're sanding, reshaping, or leveling the surface of floors and steps, diamond-wet abrasive discs are up to the task. They excel at removing scratches, stains, and other imperfections, allowing you to restore and enhance the natural beauty of stone surfaces. These discs are also highly efficient and durable. Diamond particles embedded in the surface of the disc provide excellent abrasiveness, ensuring thorough and consistent results. With their help, you can create smooth, even surfaces that sparkle and impress.

3.Tile Polishing

These versatile discs can be used with manual, automatic full, and semi-polishers to achieve superior results on all types of tiles. Whether you are working with microcrystalline, glazed, or antique tiles, wet diamond discs are available in full and semi-polished finishes. The end result is stunning brightness values that can reach over 90, giving your tiles a glossy and polished finish. These discs are especially useful for floor preparation and renovation projects involving microcrystalline tiles and tiles of all kinds. They easily remove scratches, stains, and blemishes, leaving your tile surfaces looking new and revitalized.

4.Ground Renovation

Floor refinishing is the process used to refurbish concrete floors, especially in industrial settings, warehouses, car parks, and aggregate hardener floors. The process has become popular, especially in liquid hardener flooring projects. To achieve the desired results, a variety of manual grinders or reconditioning machines are available depending on the specific needs and preferences of the project. These machines can be flexibly paired with diamond wet grinding discs of different sizes for rough grinding, fine grinding, and polishing tasks. The rough grinding phase involves using the diamond grinding disc to remove any existing coatings, stains, or imperfections on the concrete surface. This step prepares the floor for further processing and ensures a smooth and even surface. After coarse grinding, the fine grinding phase begins. Diamond grinding discs of different sizes are used to refine the concrete surface, removing any residual roughness and creating a more uniform appearance. This stage helps to further enhance the aesthetics of the floor. Finally, a polishing stage is carried out using diamond grinding discs specially designed for this purpose. These discs are used to achieve a high-quality polished surface that gives concrete floors a shiny and attractive look. This step adds the finishing touches to the entire renovation process.

English

English  Português

Português  русский

русский  Chinese

Chinese  French

French  Japanese

Japanese  Spanish

Spanish  Italian

Italian