New bionic diamond film puts "armor" on precision instruments

New bionic diamond film puts "armor" on precision instruments

Key words diamond film|2020-06-02 11:50:23|Source China Science News

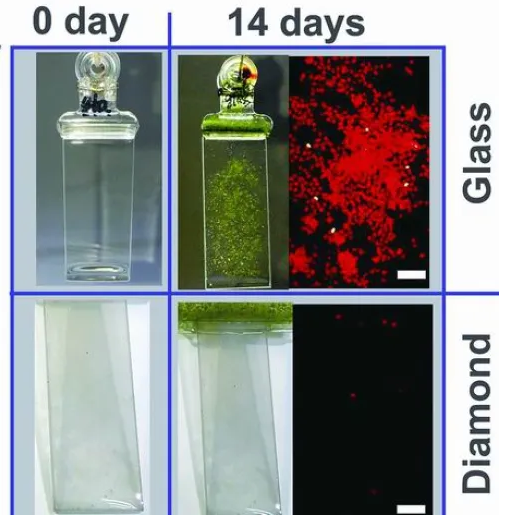

Abstract The uncoated quartz glass and the bionic diamond film were immersed in the seawater environment with green algae growth, and the photos before and after 14 days were compared with the fluorescence microscope images. Why does the lotus leaf produce silt without staining? Because the surface structure of lotus leaf has the characteristics of super hydrophobic and anti-adhesion. Drawing on this phenomenon...

Immerse uncoated quartz glass and bionic diamond film in the seawater environment where green algae grows. Compare the photos before and after 14 days with the fluorescence microscope images.

Why does the lotus leaf produce silt without staining? Because the surface structure of lotus leaf has the characteristics of super hydrophobic and anti-adhesion. Drawing on this phenomenon, the team of researchers Tang Yongbing and Zhao Ying of the Shenzhen Advanced Technology Research Institute of the Chinese Academy of Sciences has developed a new type of biomimetic diamond functional film with self-cleaning, antibacterial, anti-bioadhesion, anti-wear and anti-corrosion properties. Published in "ACS Applied Materials and Interfaces".

"In seawater, the adhesion and accumulation of microorganisms on marine instruments will lead to instrument fouling and functional degradation, affect the development of the marine industry, and even cause economic losses of hundreds of millions of yuan. The bacteria attached to medical devices, Will cause infection and affect human health." Team member Wang Tao said that the results can provide solutions for the field of medical protection and anti-fouling of marine instruments.

New low-cost preparation method

The water drops drip on the surface of the lotus leaf and rolls down quickly. What is the principle? It turned out that the surface of the lotus leaf has a micro-nano structure with small thorns, so its contact angle is large, and dirt and water droplets are not easy to attach. The research team applied this concept to the research.

Different from the traditional preparation method of diamond thin film, the team independently developed a "step-by-step planting vapor deposition method", selecting diamond nanopowder as the coating material, and uniquely using "two times planting" in the pre-treatment process to successfully construct It produces a super-hydrophobic micro-nano graded diamond functional film that is uniform, controllable, and has a bionic structure of plant leaves.

"Due to the rapid aggregation of traditional diamond nanopowder, it is difficult to control the adsorption density and uniformity. The prepared diamond micro-nano structure is uneven and difficult to control, resulting in the inability to adjust various properties. The super-hydrophobic and antibacterial effects of diamond Can't play it well." Wang Tao said.

"The so-called two-time seeding is like'seeding seeds'," Wang Tao metaphorically said. "In the first seeding, the diamond nanopowder was treated to have the same electrical properties as the surface of the material. According to the principle of repelling with the same electricity, A thin and uniform film will grow; during the second seeding, the diamond nanopowder will be treated to have different electrical properties from the surface of the material. According to the principle of different electric phase attraction, the diamond nanopowder can be filled well The surface of the material grows a uniform and dense film with a micro-nano structure."

According to her introduction, "two-stage seeding" can prepare diamond thin films with micro-nano structure without using expensive instruments used in conventional preparation methods, and the preparation cost is much lower.

Rising stars in medical and marine protection

Marine vessels usually use paint to protect the hull from the adhesion and corrosion of marine microorganisms. However, there is currently no good method for the protection of some marine precision instruments.

Biocidal materials that release heavy metal ions can affect marine ecology. Anti-adhesion materials such as polymers also have shortcomings such as poor mechanical properties and low chemical stability, which affects the durability of their anti-adhesion. Therefore, it is particularly important to develop environmentally friendly, long-lasting anti-adhesion, anti-corrosion and other special materials.

The research team tested the new biomimetic diamond film developed by simulating a complex marine environment and found that the film did not change its physical and chemical properties after immersed in corrosive liquid for one month, and its antibacterial properties remained unchanged.

"In order to test the performance of the film, we built an algae outbreak marine environment and found that the bionic diamond film reduced the adhesion of green algae by more than 95%, and the commercial materials that were not coated were already covered with algae." Wang Tao told " China Science News.

At the same time, the research team found in the test that the titanium alloy coated with the bionic diamond film inhibited the adsorption of 99% of E. coli compared with the uncoated titanium alloy. Therefore, the bionic diamond film can also be applied in the field of medical devices.

At present, this method can realize the preparation of bionic diamond thin films on a variety of complex shaped substrates and a variety of commercial substrate materials, including titanium alloys, silicon, quartz glass and ceramic substrates. As a new type of antibacterial and bioadhesive material, it has a good application prospect in the field of high-end medical devices and marine precision instruments.

Related paper information: https://doi.org/10.1021/acsami.0c02460

✔Contact us, you will get more than what you see.

-All diamond tools can be ordered and fabricated!

Henry Wang | Quote Manager

-WhatsApp:+0086 134 5903 5657

-Email: ceo@zdiamondtools.com

-Web www.zdiamondtools.com

-Web www.zliontools.com

-Web www.stone-tool.com

-Web www.z-lion.com

English

English  Português

Português  русский

русский  Chinese

Chinese  French

French  Japanese

Japanese  Spanish

Spanish  Italian

Italian